Five ways to elevate your building design with glazed bricks

/With the innate quality and design versatility of bricks, the lustrous finish of a glazed brick can add a luxe, unexpected texture to thought-provoking facades.

We have been architectural magpies and found the glossiest, shiniest Wienerberger glazed brick projects in our archives. Let’s take a closer look at how high-shine bricks were used on these eye-catching design schemes and why they were chosen to transform commercial and residential spaces.

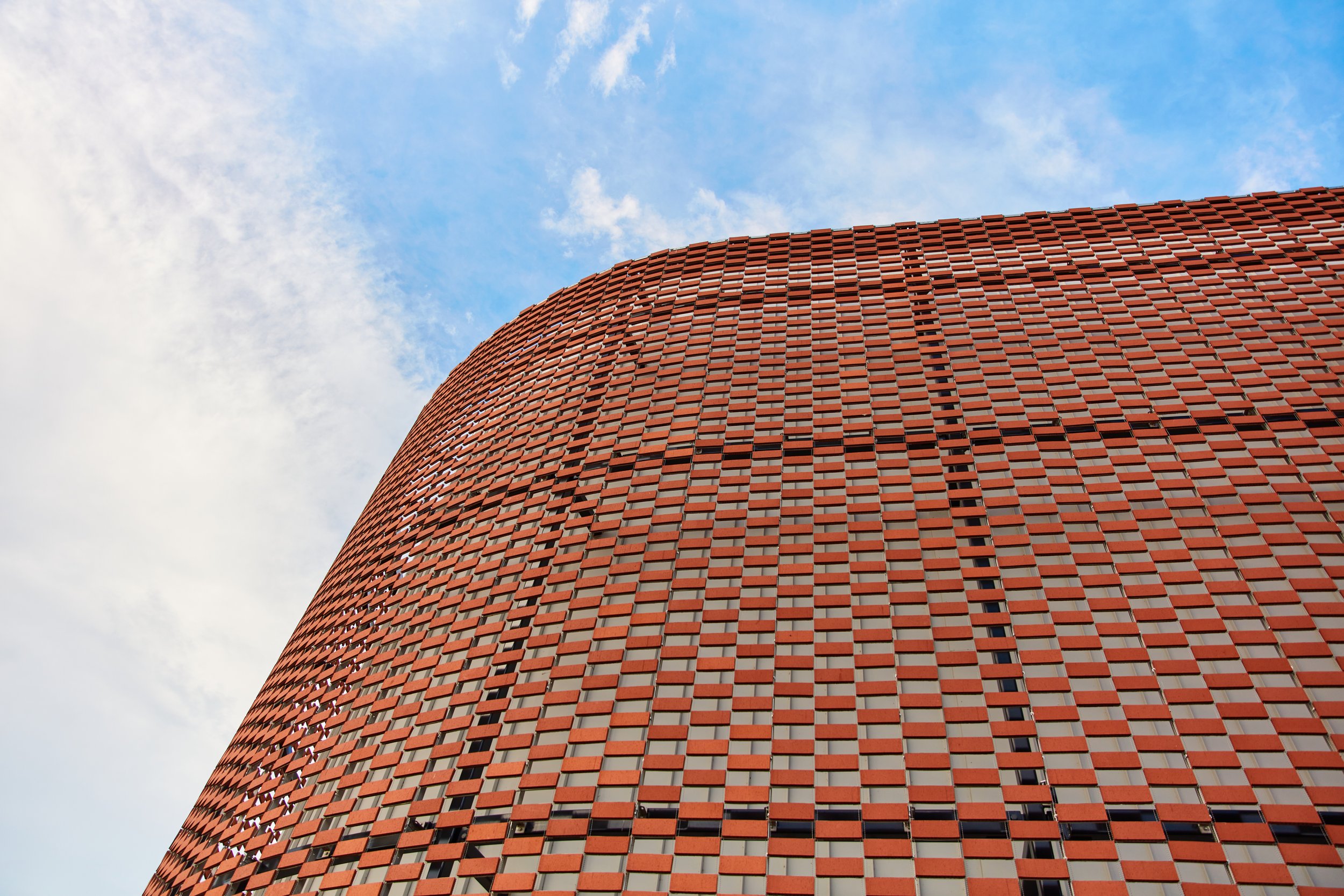

Creating striking high rise structures

Inspired by the waterfront high rises of Manhattan and Chicago, Glenn Howells Architects used the eye-catching shine of glazed bricks to achieve a cosmopolitan, international appeal on the London City Island development at Leamouth Peninsula in East London.

Each of the twelve residential buildings, between 10 and 25 storeys high, feature brick facades that give the individual structures their own identity, whilst also working together to create a strong overall composition. With brick being a smart design choice due to its versatility and London’s affinity for the material, some buildings used a natural texture, whilst three of the twelve feature a glazed finish.

Red, blue and white glazed bricks were chosen so that these shades could be as vibrant as possible, which is difficult to accomplish with a standard brick. All bricks in each shade came from a single production run so a uniform colour could be achieved when installed to the full height of the facade for maximum impact.

Putting style back into the High Street

After a decline in popularity of Swansea’s tired high street, this regeneration project by Coastal Housing Group had the ambition of once again making this area the commercial heart of the city.

The Swansea Urban Village project created new retail units for the High Street as well as Wales' first 'Creative Cluster', as part of a residentially led city centre mixed use regeneration.

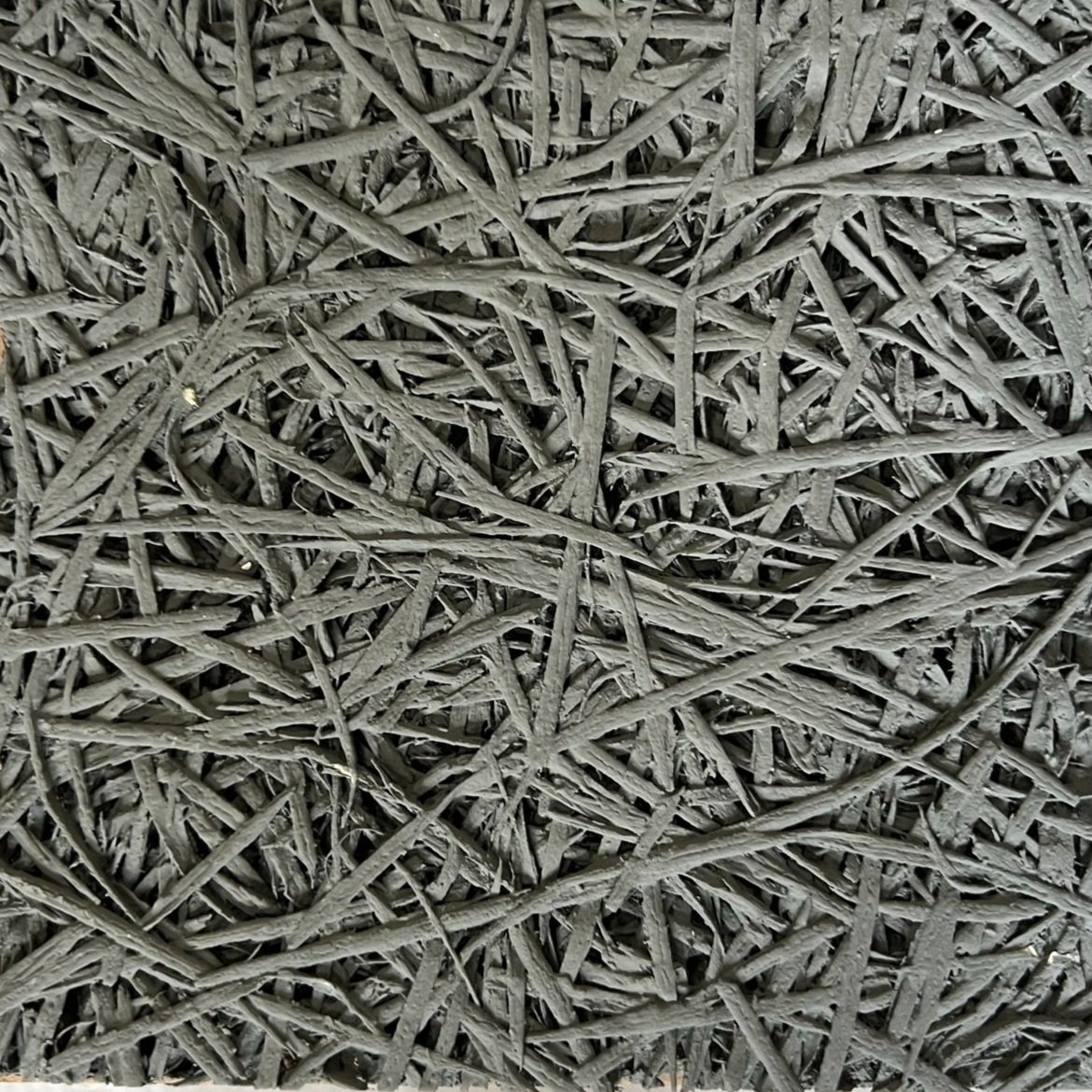

For the southernmost building in this scheme which acted as the “front-door” to the development, Holder Mathias Architects chose dark green glazed bricks with white mortar. To add further interest to the facade, the brickwork was broken up by pre-cast Portland Stone bands, ensuring that the architecture complemented the local area.

Adding lustre both inside and out

Yotel London City is a 4 star hotel situated within the creative hub of Clerkenwell, so its design had to pack an extra punch, whilst also representing the Yotel brand and cohesively sitting alongside local architecture.

When Fletcher Rae architects picked up the Yotel project with full planning approval already in place, they enlisted the help of Wienerberger to provide the ceramic glazed brick product stipulated in the plans.

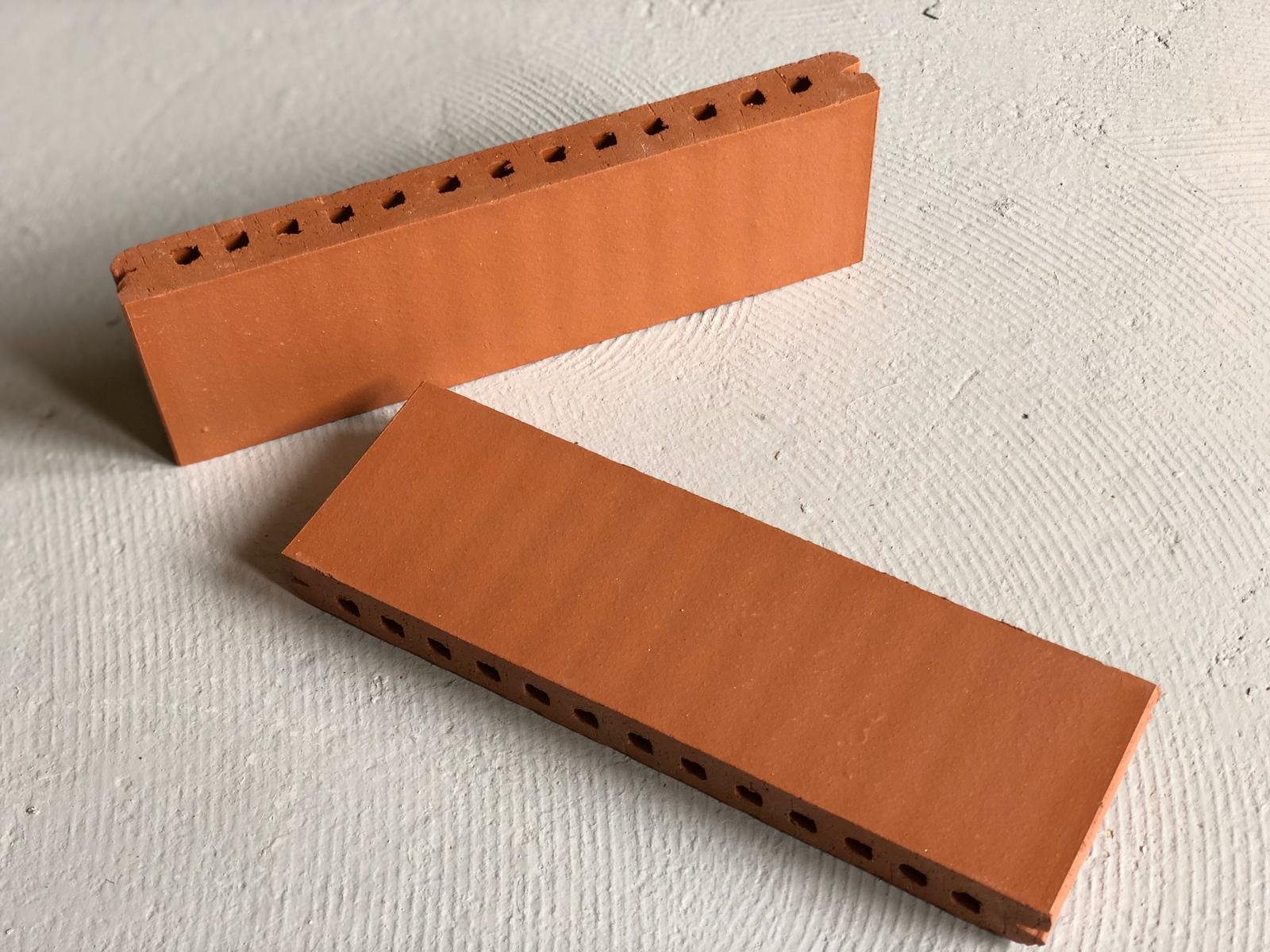

As well as providing enough high-quality glazed bricks to meet the construction programme and project budgets, Wienerberger also created multiple glazed special shaped bricks to avoid the use of cut bricks, which would have blemished the overall flawless finish of the facade.

The hotel’s main facade features a subtle taupe glazed brick in an English bond, with a bold red glazed brick guiding you to the rear square through a walkway. The use of glossy taupe bricks is extended through into internal spaces, offering a more sophisticated twist on the exposed brick trend for the contemporary lobby area.

Bringing luxury to affordable housing

Glazed bricks don’t have to be used for a full facade to add richness to a design scheme. Considered and smart placement of glazed bricks alongside more traditional bricks or alternative building materials can add a pop of vibrant colour and provide the functional purpose of creating zones.

The Wardroper House affordable housing project in the evolving Elephant & Castle area of London used contrasting textures on its facades - glazed bricks solely on the ground floor of the building, with timber cladding on the above floors.

Sarah Wigglesworth Architects describe their design as a “collage of fragments of (the area’s) heritage,” referencing the eclectic architectural context it stands in. The bottle green glazed bricks were chosen as a tribute to the local Victorian corner pubs and terraces, with the contemporary cedar cladding blending in with the more modern high rise residential developments in the vicinity.

Enhancing beautiful homes

Green with a sheen was the chosen effect for this eye-catching double storey extension at a home in Zurenborg, Belgium.

With the existing body of the house and the facade visible from the street constructed using a traditional red brick, the architects (P8-Architecten) and their client chose to opt for a material that contrasted rather than blended in to the background for this exciting new addition at the rear.

The green glazed bricks used on this project give a fresh, contemporary aesthetic whilst, thanks to the shade selected, working harmoniously with the climbing plants and garden space. By adding intelligent design details such as glazed bricks laid in both horizontal and vertical orientations, the scheme becomes expressive with a hint of luxury.